The new Canyon Aeroad is a really cool bike. It ticks all the boxes for me: it’s got serious aero credentials, it is light, it is quite inexpensive for what you get, you can run mechanical and electronic drivetrains, and there is a stock Campagnolo build option. But I would NEVER get one. Here’s why:

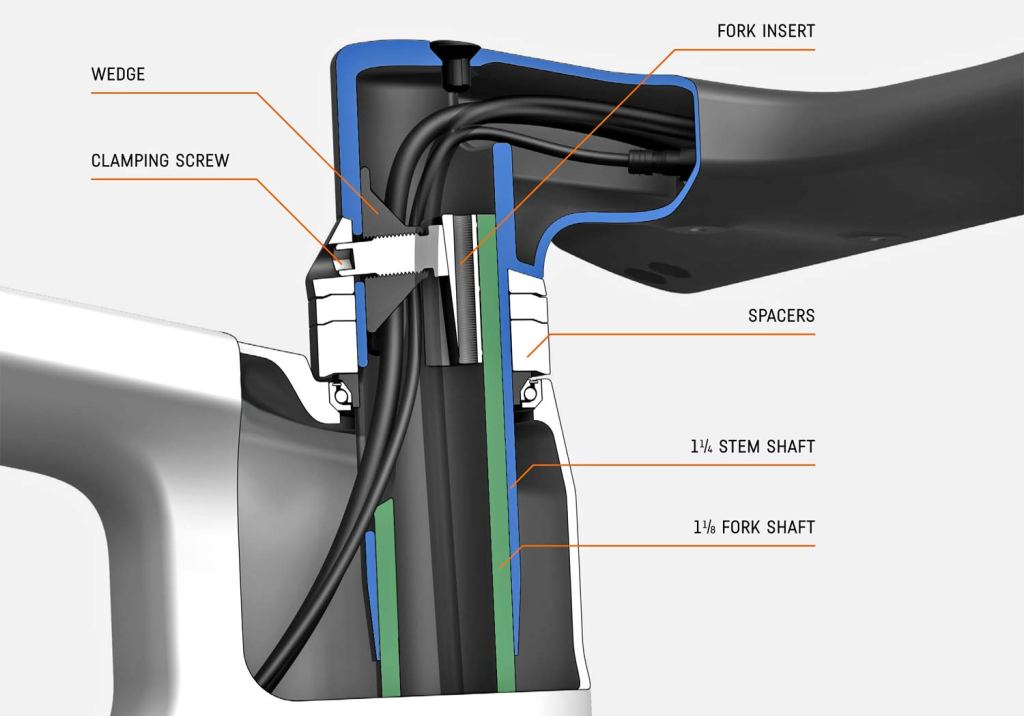

This is a cutaway of the front end of the bicycle. Right away we can see some issues:

- The total stack adjustment is only 15mm. FIFTEEN. As in little more than half an inch. Good thing they have eight sizes… they’re going to need them.

- Tiny upper headset bearing. This is typical of Canyon, and not usually a problem as long as you maintain proper preload.

- Cables threaded through the bearing- if the bearing fails, you get to replace the upper bearing and (!) re-bleed both of your brakes. Fun. (especially if you run SRAM)

- Giant hole on the back of the steerer tube and stem where the cables pass through.

- No provision at all for a standard bar and stem combination for athletes who don’t get along with the Canyon bar/stem.

However, the most egregious issue is one that’s not immediately evident.

I am disappointed in the way they designed the preload mechanism. For a start, there is only one bolt to simultaneously hold the stem onto the fork and also provide preload to the bearings. In order to set the initial preload, a long “preload tool” which is essentially a bolt with a handle, is required. My best guess at why this wasn’t just a standard preload bolt is because it let them build the stem lighter to not have it.

It only gets worse after initial preload is set. The “clamping screw” in the below diagram does not have any locking mechanism! Let me explain why this is a problem. In normal operation, a bicycle fork experiences bumps, shock loads, and vibration. Typically, in applications that have these types of loads, a locking mechanism is incorporated, to prevent loosening during operation. One easy example is a cup and cone hub. To adjust the bearings, you tighten or loosen the “cone” into the “cup,” and while holding that position with a specially designed “cone wrench,” you tighten down a locknut to prevent it from moving (for more info, check out Sheldon Brown). The same principle is used in quill stem headsets, in older square tapered bottom brackets… heck most bearing applications use some form of mechanical locknut to prevent movement over time. This is especially important in- you guessed it- applications with shock loads and vibration.

“But wait!” you say. “Surely, there must be another way?” And of course, there are many. There are plenty of applications that don’t use a locking nut configuration that hold together just fine. Loctite is essentially thread glue that gums up threads to help prevent bolts from coming loose. Installing a spring/split washer under the head of a bolt provides mechanical preload, helping to prevent loosening. You can also install a set screw orthogonally to the main screw, pushing on the threads of the main fastener and preventing it from turning.

The problem is, it would be inadvisable to use Loctite in this application as it would change the torque spec unpredictably in a critical area. There isn’t an obvious way to use a lock washer or to install a set screw. So here we are. One bolt! There is no redundancy at all in the system- once the bolt starts to loosen a little bit, the headset comes loose AND the bars become loose on the steerer tube. There could very well be a situation where loose headset induced speed wobble could cause the bars to slip on the steerer tube, resulting in a total loss of control and a catastrophic incident. Not to mention that the carefully calculated load paths through the composite structure will change dramatically when a loose headset changes a significant portion of the inputs. I’m sure Canyon has done their homework to make sure that this is strong and durable given perfect adjustment- however, I’m not at all convinced that they thought through the failure modes and the effect that they will have on the system should they come to pass.

EDIT TO ADD: I’ve had a few people comment on whether this is any different than a single bolt stem (which have been around for forever!). The answer is an emphatic YES. On a typical stem, both sides of the clamped joint are stiff laterally and are part of the same structure. The stem bolt is also under tension. On the Canyon, the bolt is under compression and the two sides of the joint are different parts that can rotate and translate relative to each other. The other big issue is that in thin walled composite structures, a fair amount of flex is to be expected, and given that both sides of this joint compress onto different thin walled surfaces, it is possible for relative movement to occur, which inevitably ends with a loosened bolt.

Most importantly, however, is the fact that if your headset or stem bolt gets loose on a conventional bike, the failure mode is a wobbly front end OR loose handlebars, not both, and it is easily repairable roadside. Not so with the new Canyon.